The proper securing of cargo and transportation is related not only to the packaging of the goods in question or the issue of the road itself and the passage. It is also important to properly arrange the transported items and protect them from shifting and bumping during transport. Transport belts are helpful and sometimes necessary for this. Regulations for their use and their implementation are a guarantee of transportation without damage or loss.

Transport belts and their types

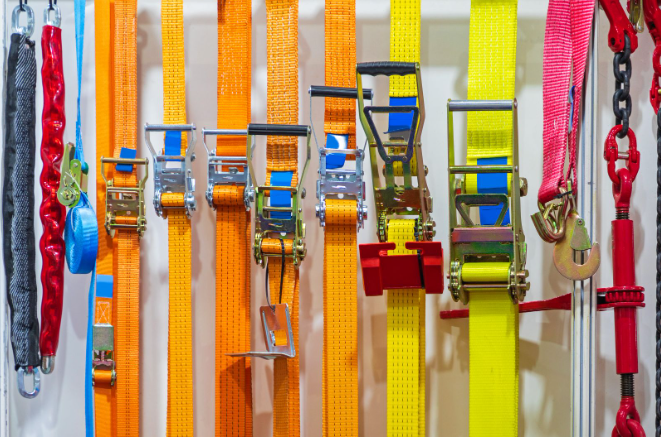

Transport belts, also known as lashing belts, are available in many different variants, so they are widely used not only for transporting and securing cargo. Increasingly, they are also used for immobilizing cars on a trailer, fixing banners and large-format advertisements or in warehouse space.

You can distinguish between one- and two-piece transport belts, three-point belts, belts with hooks, tie-downs or various types of fasteners. Models with a tensioner are also a popular type of conveyor belts, as well as tailor-made and equipped with a variety of ends. However, in order for these accessories to perform their functions, the parameters and labels that the conveyor belts bear are important. Regulations for the proper use of conveyor belts also include special standards that each such item should meet.

Transport belts – regulations vs. types of labels

There are 3 colors of labels for conveyor belts:

- blue – denotes a universal belt, most often made of polyester, which is resistant to mineral acids and shows its properties when used at temperatures from -40 to 100 degrees Celsius,

- green – denotes a belt made of polyamide, which is not resistant to mineral acids and retains its properties in the same temperature range as belts with a blue label,

- brown – indicates a belt made of polypropylene, not resistant to mineral acids. Such fastening belts retain their properties at temperatures from -40 to 80 degrees Celsius.

When using lashing straps, it is also necessary to pay attention to their width and strength, and then adjust the appropriate accessory to the weight of the load, keeping a certain margin.

At the same time, it is very important to pay attention to whether a particular lashing belt shows strength in tension and strength in strapping at the same time. If the accessory is designed for only one of these activities, it should not be used for the other.

What standards should conveyor belts meet?

Robust transport belts should simultaneously be resistant to adverse weather conditions and comply with the strict regulations that apply both in Poland and in international transport. Safe and sturdy accessories of this type meet the standards of the highest quality and bear the European standard, which in Poland is valid under the number PN-EN 12195-2:2003, in accordance with the Regulation of the Minister of Infrastructure of January 25, 2018 on the method of transporting cargo, in force since 2004.

However, when carrying out transport orders of various types, it is useful to have several different conveyor belts, as well as replacement models. Transport belts are products that are often subject to heavy use and abrasion, and their damage cannot always be predicted in advance.